Snapmaker U1 Color 3D Printer Blends Blazing Speed With Less Waste

Most 3D printers force you to choose between speed, color, quality, or price. You can have fast prints, but only in one color. Multi-color prints take forever and waste enormous amounts of filament. Professional results require expensive machines that most makers can’t justify.

The Snapmaker U1 Color 3D Printer refuses to accept these compromises. This isn’t just another incremental improvement but a fundamental rethinking of how desktop 3D printing should work. It’s designed for makers who want everything: speed, color, precision, and sustainability.

Designer: You Li

Click Here to Buy Now: $749 $999 ($250 off). Hurry, only 411/3500 left! Raised over $6.2 million.

A New Approach to Multi-Material Printing

Traditional consumer 3D printers rely on single-nozzle systems that require time-consuming filament swaps and produce mountains of waste. Every color change means flushing perfectly good material, creating wasteful piles of purge that often use more filament than the actual print.

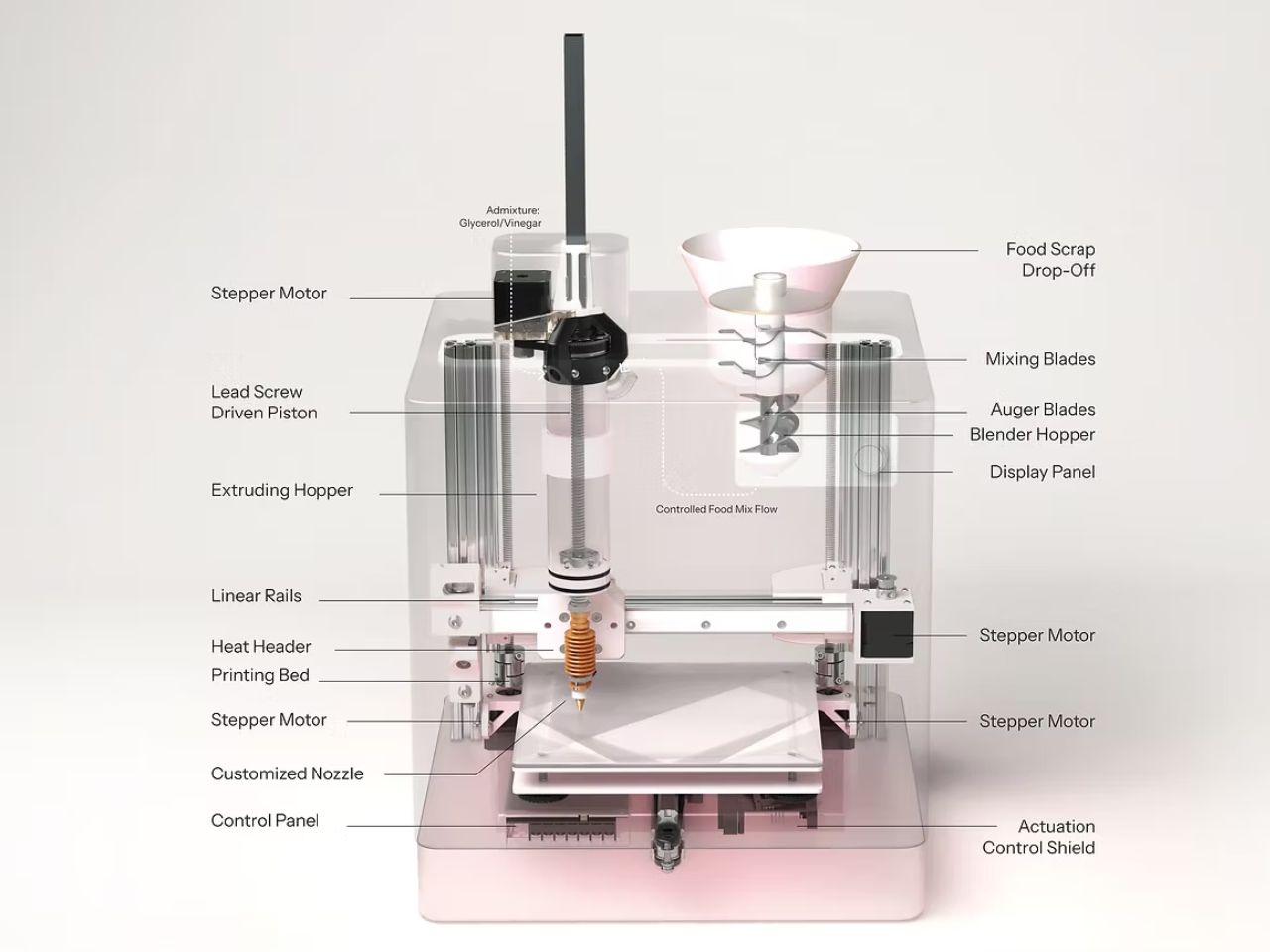

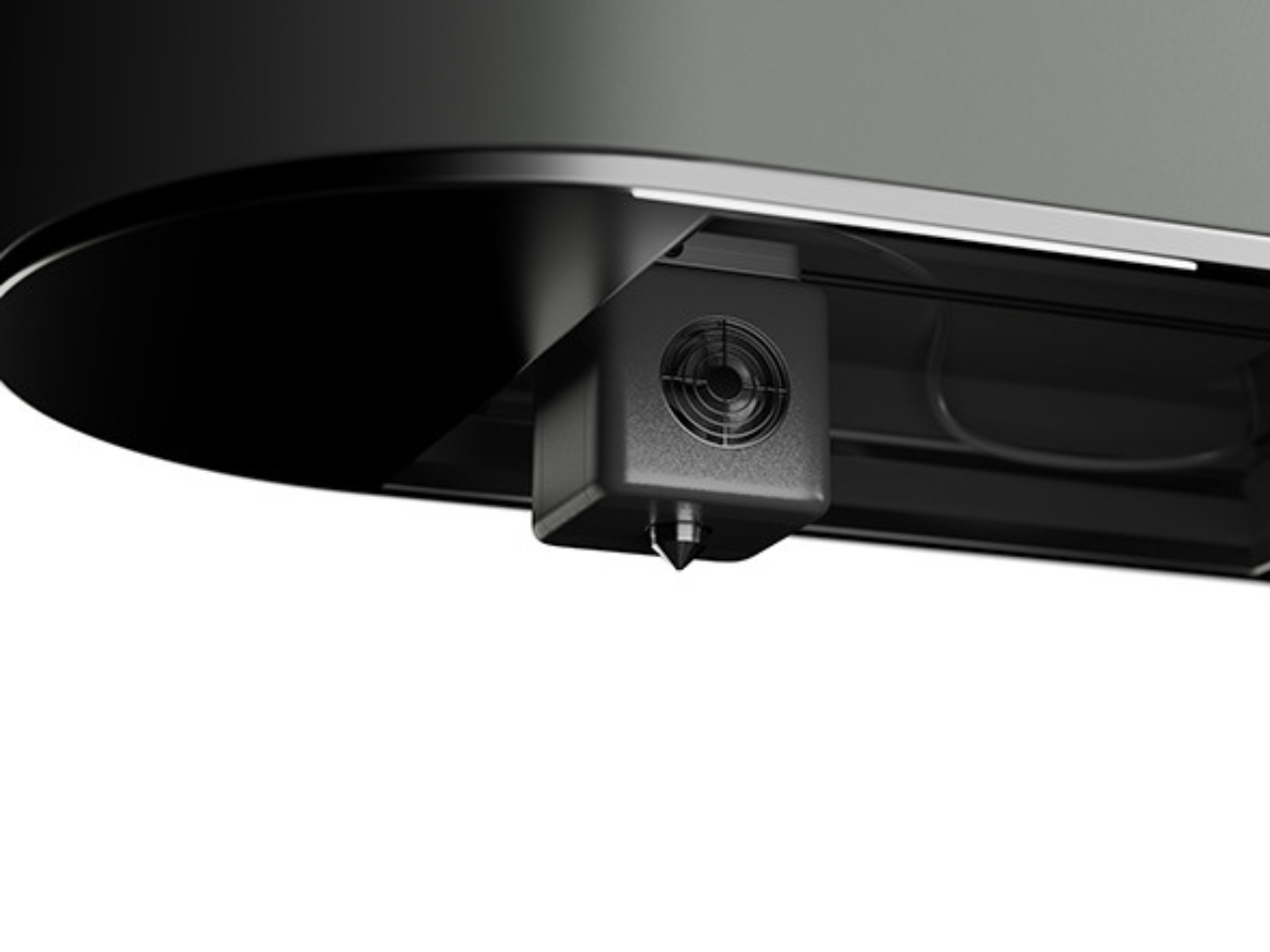

The Snapmaker U1 introduces a four-head tool-changing system that allows multi-color and multi-material prints in a single job. Each toolhead is physically separate, eliminating cross-contamination and enabling seamless transitions between colors and materials. This approach mirrors professional industrial printers but brings the technology to desktop users.

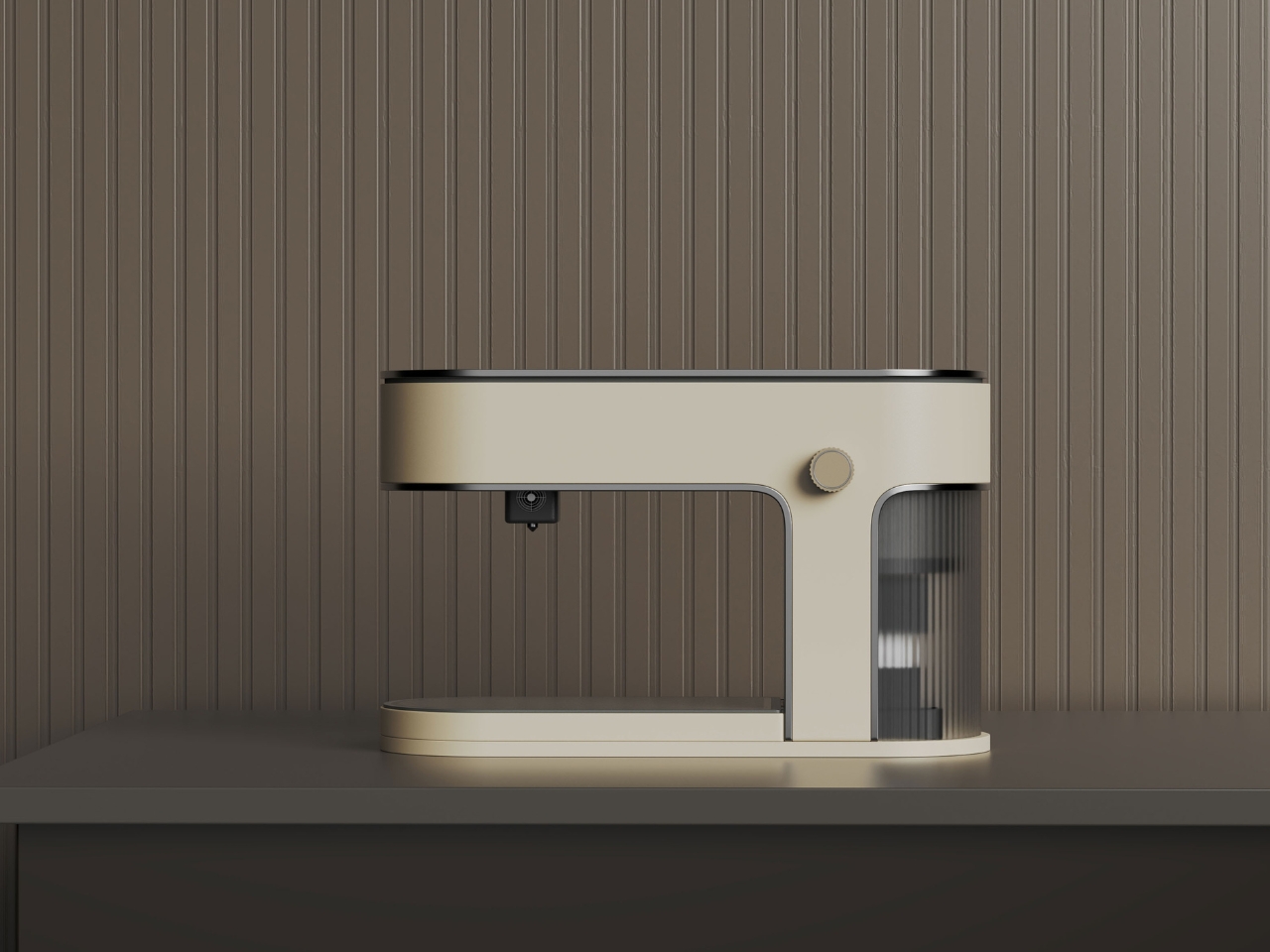

Design Philosophy and Brand Confidence

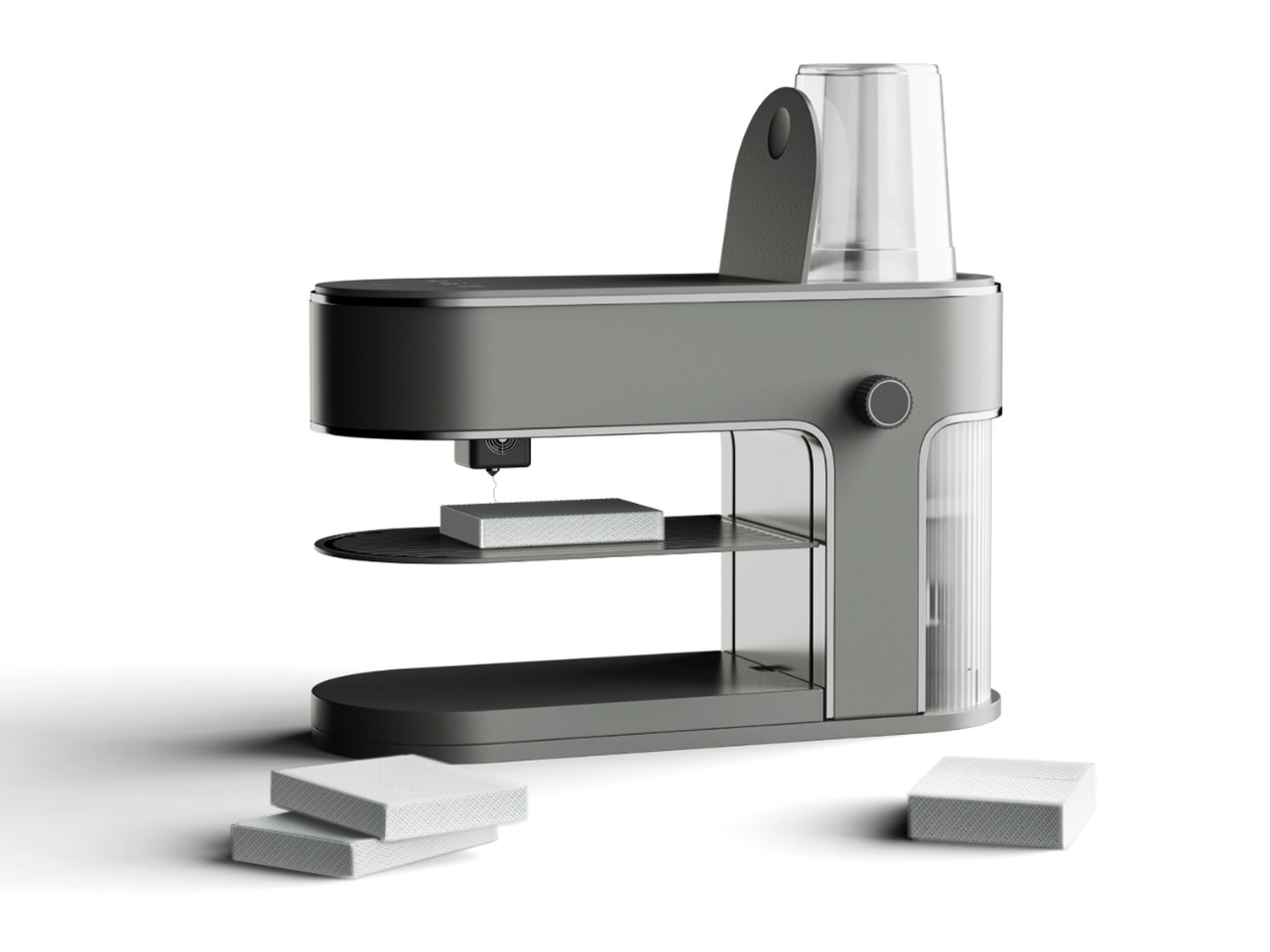

Snapmaker has built a reputation for reliable, innovative desktop fabrication tools that actually deliver on their promises. The U1 continues this tradition with a modular CoreXY design that looks as advanced as it performs. With an aesthetic plastic shell and careful attention to engineering, this creation tool is designed from the get-go to be accessible, both in terms of cost as well as functionality.

The machine’s visual design reflects its technical sophistication. The Snapmaker U1 has a transparent back panel that complements its open front, allowing it to visually flow more naturally into your workspace. Clean lines, thoughtful component placement, and a transparent approach to showing its capabilities create a printer that’s as much a statement piece as a production tool.

SnapSwap : Fast, Waste-Free Tool-changing

: Fast, Waste-Free Tool-changing

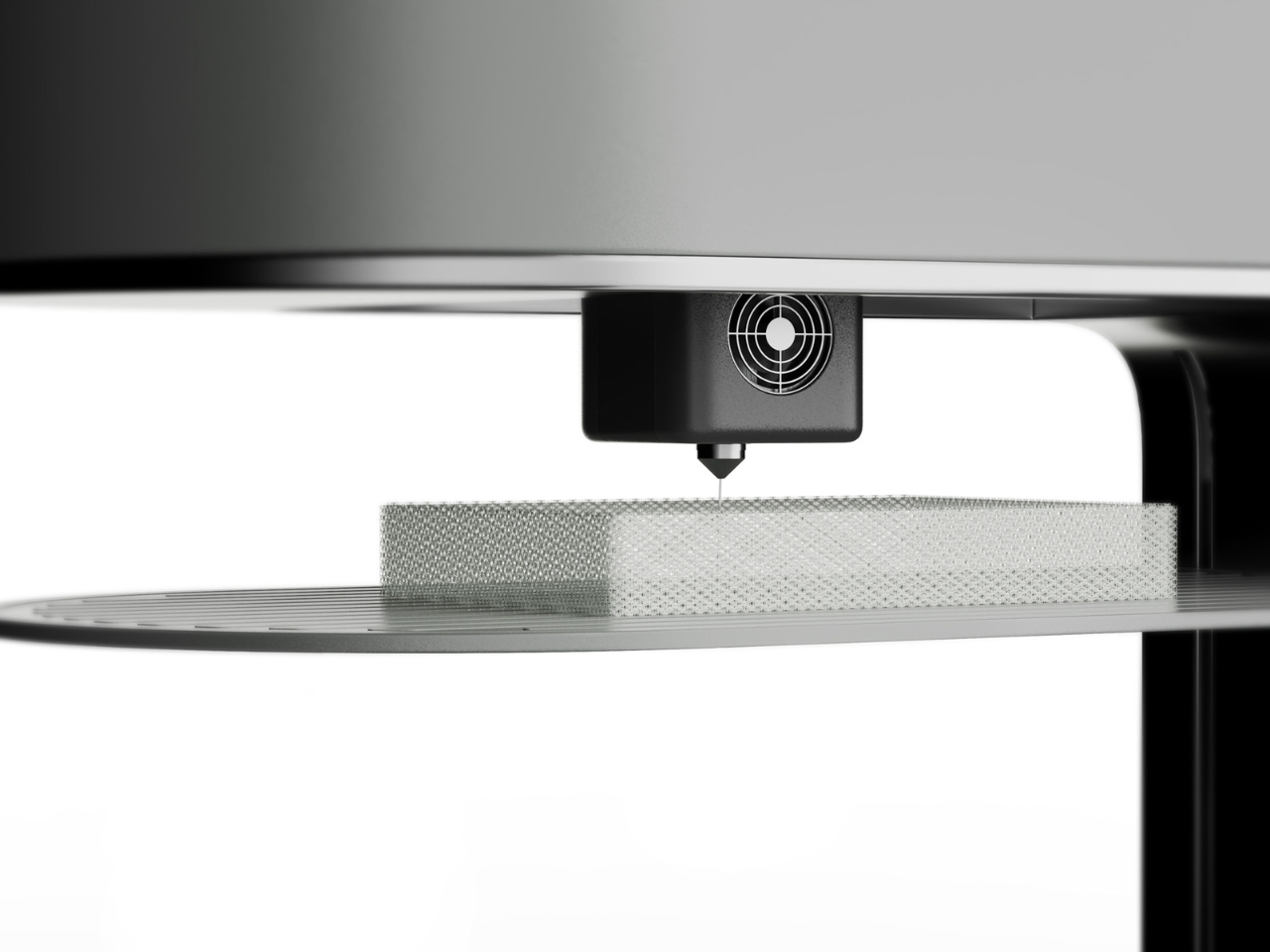

The SnapSwap system enables physical toolhead swaps in just five seconds, transforming how multi-material printing works. This avoids the little balls of perfectly good filament, wasted by typical AMS style machines, and reduces filament waste by up to 80% compared to traditional systems. The precision is remarkable: automatic toolhead alignment stays within 0.04mm for sharp, clean prints.

system enables physical toolhead swaps in just five seconds, transforming how multi-material printing works. This avoids the little balls of perfectly good filament, wasted by typical AMS style machines, and reduces filament waste by up to 80% compared to traditional systems. The precision is remarkable: automatic toolhead alignment stays within 0.04mm for sharp, clean prints.

Consider a four-color dragon figure that takes five hours on the U1 versus thirty hours on conventional printers. The U1 uses just 96 grams of filament, while others waste 483 grams on the same model. It even boasts up to 80% electricity savings! That’s not just efficiency but a fundamental shift toward sustainable making.

Speed, Precision, and Print Quality

The CoreXY motion system delivers print speeds up to 300mm/s with travel speeds reaching 500mm/s and acceleration hitting 20,000mm/s². These aren’t just impressive numbers but translate into real-world time savings without sacrificing quality. Smart calibration features include mesh bed leveling and active vibration control.

The large 270 x 270 x 270mm build volume accommodates both ambitious single prints and efficient batch production. Pressure advance compensates for flow delays, ensuring accurate prints with crisp details even at high speeds. Stainless steel nozzles support a wide range of filaments, with hardened steel nozzles and even new nozzle sizes on the way.

Eco-Friendly Innovation

The SnapSwap system’s waste reduction goes beyond cost savings to address environmental concerns. Using large amounts of filament typically wasted during color changes aligns with growing demands for sustainable maker tools. This isn’t greenwashing but genuine material efficiency.

system’s waste reduction goes beyond cost savings to address environmental concerns. Using large amounts of filament typically wasted during color changes aligns with growing demands for sustainable maker tools. This isn’t greenwashing but genuine material efficiency.

The environmental impact extends beyond individual projects. When scaled across thousands of users, the waste reduction becomes significant. It’s the kind of innovation that makes 3D printing more responsible without sacrificing capability.

Smart Automation for Effortless Printing

The automatic filament system holds four spools with RFID recognition, auto-loading, and backup mode functionality. This eliminates manual intervention during long prints and ensures consistent material flow. The built-in AI camera captures time-lapses while monitoring for anomalies and print failures.

Snapmaker Orca Slicer provides engineer-tested profiles optimized for the U1’s capabilities. The companion app enables remote print management, real-time monitoring, and instant alerts when issues arise. Failure detection covers air printing, filament run-out, and power loss recovery.

The Snapmaker U1 represents a leap forward in accessible, high-performance 3D printing. It empowers makers to create more while wasting less, exploring new creative possibilities in a machine that’s as visually impressive as it is technically advanced. Sometimes the best innovations come from refusing to accept the limitations everyone else considers inevitable.

Click Here to Buy Now: $749 $999 ($250 off). Hurry, only 411/3500 left! Raised over $6.2 million.

The post Snapmaker U1 Color 3D Printer Blends Blazing Speed With Less Waste first appeared on Yanko Design.